E-mail: sales6@lithiumbattery-rj.com | Tel: 0086-13430203848

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

RJ-BESS323

RJ TECH

RJ-BESS323

RJ TECH BESS - Fully Certified - FACTORY PRICE

RJ has a powerful engineer team who have professional skills in mechanical design, thermal management design, simulation , electric design and software design. Engineering team have more than 10 years experience in battery system design, including many world famous projects for different area around the world. Our worker are well trained in professional skills to ensure the quality and lead time. Battery module are designed for full automatic production line for easy scale up to mass products.

High-valued assets should be used frequently and efficiently to maximize the owner’s return on investment. To minimize the total cost of ownership, the best battery chemistry and system level performance can be tailored to optimize the application’s operational requirements.

Aseismic design & cooling design & heating design based on the real working condition.

Anti-corrosion case & Strict IP test to ensure marine battery pack with excellent protection from water and dust. All connector are well designed from water protection and vibration. Provide full solution for marine engine, working well with the solar panel & inverter & water proof charger.

| Model | RJ-BESS323 |

| Norminal Power(KWh) | 323KWH |

| Inverter Power | 150KW |

| MPPT Power | 195KW |

| Material Type | Lithium Battery (LiFePO4) |

| Dimensions (mm) | 2200*2100*2200mm |

| Weight(Kg) | 4500 Kg |

| Isolation | Transformer Cabinet With Power Panel |

| Module Balance | Active Compensate Balance |

| Cooling | Force-Air Cooling(Indoor) Outdoor with AC |

| Enclosure | Stainless Steel container |

| Expansibility | parallel connection for Mwh system |

| Installation Methode | Floor Mounted |

| Communication Port(Optional) | RS485 / RS232/CANBUS/WIFI |

| Working Temperature(℃) | -20~65℃ |

| Humidity | 0-95% RH |

| IP Grade (IP) | IP54-IP68 |

| Altitude | ≤3000m |

| Authentication Level | Fully certified for EU & North America |

| Design Life(year) | 15+ years |

RJ has successfully developed a new version Battery Management System (BMS) for lithium based batteries, which is designed that operates more efficiently and communicates with UART between master and slave modules and can communicate via CAN protocol with external devices.

Micro controller based control and protection equipment is designed that help to measure and monitor the voltage, temperature and current values of the batteries.

They protect the battery cells from the conditions such as over charge, over discharge, high current, high temperature.

BMS balances battery cell voltages during charging process with passive cell voltage balancing.

In addition to the main controller module in the BMS, slave controller modules have been added to provide high resolution voltage and temperature tracking.

A modular BMS has been devised which can be used in groups of batteries of different voltage values thanks to electrically isolated slave control modules.

Master and Slave BMS

CAN communication (optional)

GPS function (optional)

APP for checking battery data (Optional)

Voltage \current\temperature\short circuit protection

Real time dynamic calibration

Vehicle operation condition was considered

Multi-method combination

High accuracy measurement of the cell voltage /temperature/pack current

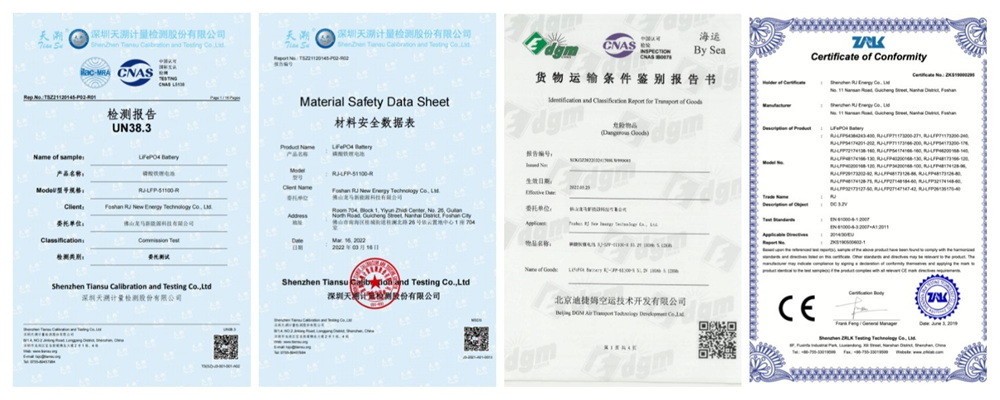

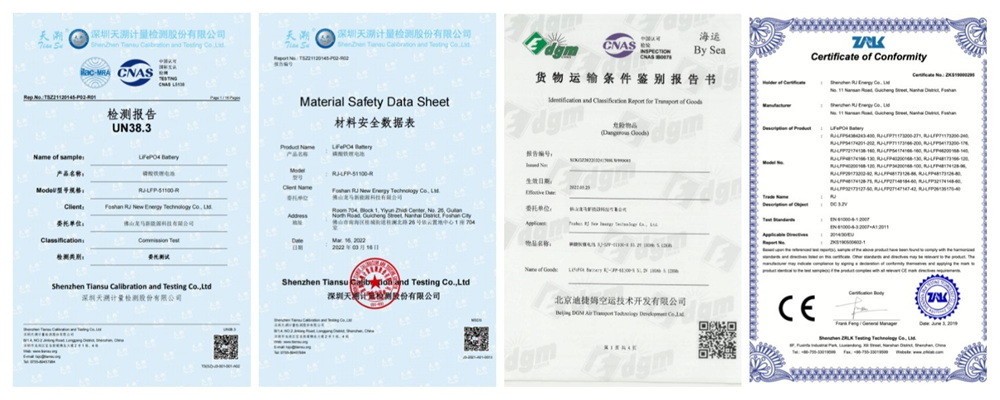

RJ TECH Batteries Certifications

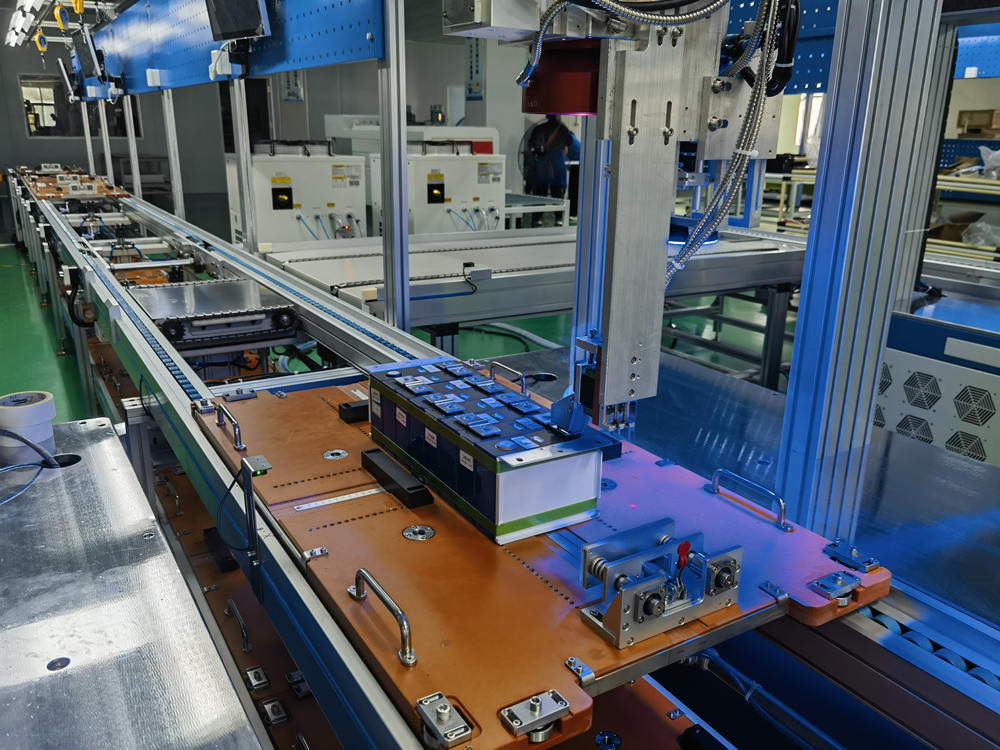

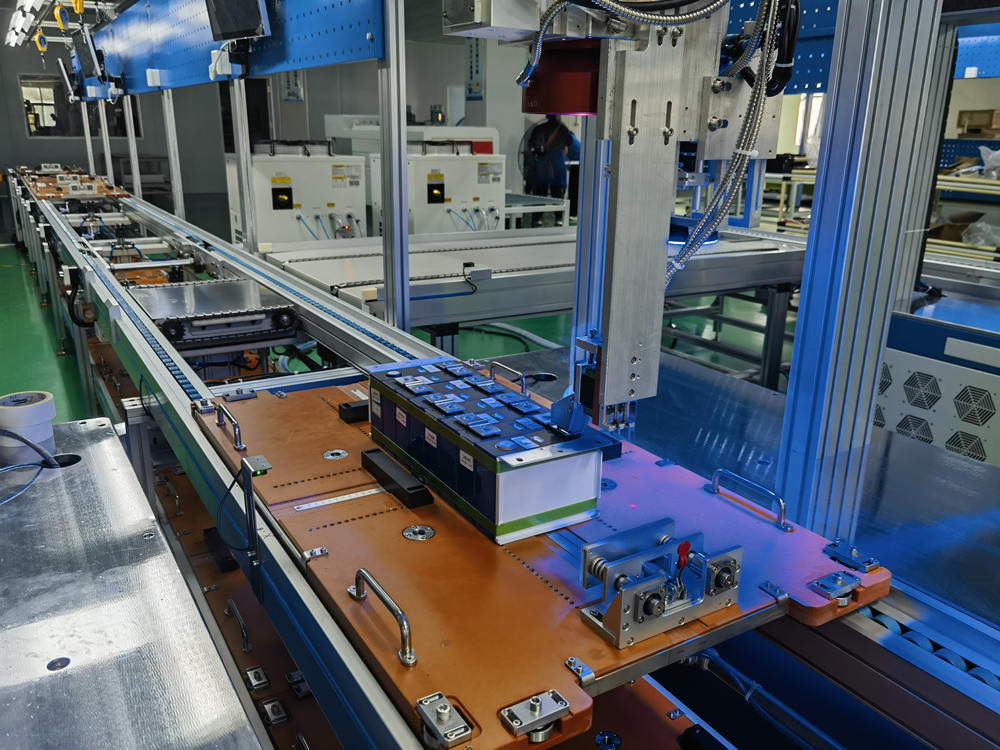

RJ TECH ISO9001 Factory Automatic Production Line

CONTACT US GET A LATEST QUOTE NOW!

RJ TECH BESS - Fully Certified - FACTORY PRICE

RJ has a powerful engineer team who have professional skills in mechanical design, thermal management design, simulation , electric design and software design. Engineering team have more than 10 years experience in battery system design, including many world famous projects for different area around the world. Our worker are well trained in professional skills to ensure the quality and lead time. Battery module are designed for full automatic production line for easy scale up to mass products.

High-valued assets should be used frequently and efficiently to maximize the owner’s return on investment. To minimize the total cost of ownership, the best battery chemistry and system level performance can be tailored to optimize the application’s operational requirements.

Aseismic design & cooling design & heating design based on the real working condition.

Anti-corrosion case & Strict IP test to ensure marine battery pack with excellent protection from water and dust. All connector are well designed from water protection and vibration. Provide full solution for marine engine, working well with the solar panel & inverter & water proof charger.

| Model | RJ-BESS323 |

| Norminal Power(KWh) | 323KWH |

| Inverter Power | 150KW |

| MPPT Power | 195KW |

| Material Type | Lithium Battery (LiFePO4) |

| Dimensions (mm) | 2200*2100*2200mm |

| Weight(Kg) | 4500 Kg |

| Isolation | Transformer Cabinet With Power Panel |

| Module Balance | Active Compensate Balance |

| Cooling | Force-Air Cooling(Indoor) Outdoor with AC |

| Enclosure | Stainless Steel container |

| Expansibility | parallel connection for Mwh system |

| Installation Methode | Floor Mounted |

| Communication Port(Optional) | RS485 / RS232/CANBUS/WIFI |

| Working Temperature(℃) | -20~65℃ |

| Humidity | 0-95% RH |

| IP Grade (IP) | IP54-IP68 |

| Altitude | ≤3000m |

| Authentication Level | Fully certified for EU & North America |

| Design Life(year) | 15+ years |

RJ has successfully developed a new version Battery Management System (BMS) for lithium based batteries, which is designed that operates more efficiently and communicates with UART between master and slave modules and can communicate via CAN protocol with external devices.

Micro controller based control and protection equipment is designed that help to measure and monitor the voltage, temperature and current values of the batteries.

They protect the battery cells from the conditions such as over charge, over discharge, high current, high temperature.

BMS balances battery cell voltages during charging process with passive cell voltage balancing.

In addition to the main controller module in the BMS, slave controller modules have been added to provide high resolution voltage and temperature tracking.

A modular BMS has been devised which can be used in groups of batteries of different voltage values thanks to electrically isolated slave control modules.

Master and Slave BMS

CAN communication (optional)

GPS function (optional)

APP for checking battery data (Optional)

Voltage \current\temperature\short circuit protection

Real time dynamic calibration

Vehicle operation condition was considered

Multi-method combination

High accuracy measurement of the cell voltage /temperature/pack current

RJ TECH Batteries Certifications

RJ TECH ISO9001 Factory Automatic Production Line

CONTACT US GET A LATEST QUOTE NOW!

RJ TECH Solar Battery LiFePO4 64kWH Battery Sol Ark 15K 2P Hybrid Inverter Closed Loop

RJ TECH 64KWH 30KWH 15KWH Solar Battery LiFePO4 Battery Sol Ark 15K 2P Hybrid Inverter

RJ TECH 51.2V 620AH 32KWH LiFePO4 Battery Deye Inverter SUN-8K-SG04LP3-EU

RJ TECH 51.2V 620AH 32KWH LiFePO4 Battery with Deye 10KW 3phase inverter in France

RJ TECH 51.2V 930AH 48KWH LiFePO4 Battery with Deye 12KW 3phase inverter in France

Home / Products / About Us / Factory Tour / Quality Control / News / Request A Quote